Robotic automation has been around for quite a while. For example, the automotive industry started using robots 60 years ago, and today, a great majority of repetitive motion and/or critical tasks are done with some sort of robotics and/or automation.

JCM has a long history of technology leadership in the gaming industry. We maintain that leadership by offering solutions that will help our customers grow and be more efficient, and automation technology is one way we can do that. JCM already uses robotic automation within our manufacturing and quality departments, which allows us to run some functions 24 hours a day.

When we first released the ICB® Intelligent Cash Box in 2001, we started down the path of being a systems provider for the gaming industry, and it also gave us an even better understanding of count room processes. After years of observing, we saw a need to develop a solution for automating the cash box handling process. This made perfect sense for us since JCM provides cash boxes, ICB provides critical information from each bill validator including the asset number of the slot machine, and we understand the importance of cash handling automation. The challenge became not if but how to reliably automate the current processes without making it too complicated.

We knew robots would play a key role. They are reliable, good at doing repetitive motion for long periods of time, and need minimal maintenance, making them extremely efficient. These factors allow the casino to use team members from these repetitive movement type jobs to reassign them to customer-facing areas where they can improve the customer experience or to perform other count room functions while ICB ASAP processes the cash boxes.

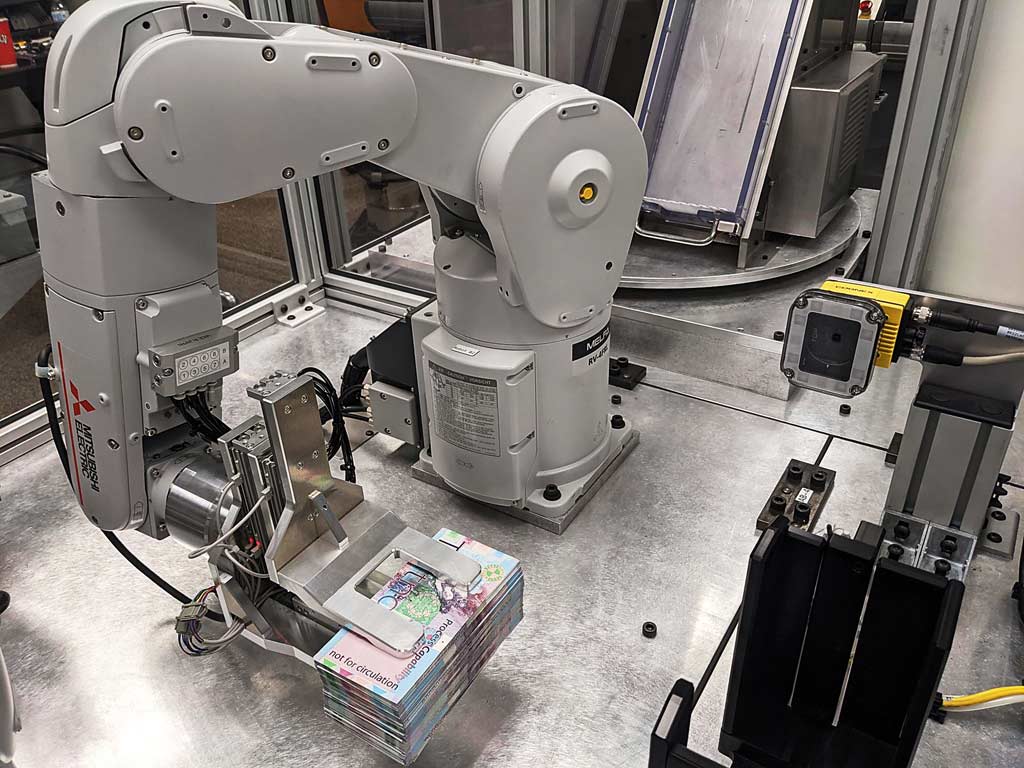

Building a system using robotic automation to help our customers was the central premise of creating ICB ASAP. As we built ICB ASAP, we used all field-proven components. This gave us the opportunity to develop a reliable solution that will keep it in operation for many years. To do that, we worked directly with Mitsubishi, other suppliers, and our robotic integrator to help specify the best components for our solution. We did this because we wanted to make sure that the components were standard and readily available.

Along with this, JCM developed all the end-of-arm tooling for each robot and critical movement to make sure it would interface flawlessly with our cash boxes. Another key requirement was an overall efficient footprint. In most cases the count room has limited space, so we needed to make sure the solution was compact while keeping installation, operator movement, accessibility, maintenance, and service in mind. Our ICB ASAP solution can be moved through standard size doors, set up and operating in a few days.

We also wanted to keep the operator in mind. Because most operators in a count room are not familiar with robotic automation, we did not want the casino to have to hire a specialized operator. With the ICB ASAP HMI (Human Machine Interface), we made sure the functions are clearly labeled, easy to start, stop, identify issues, and recover without having a technical person onsite.

As JCM moves forward with enhancements to ICB ASAP and new technology, automation will be on our roadmap and play a big role in the future of JCM and the gaming industry.